Study confirms: milled prosthesis material performs better than 3D-printed

For the recently published international study, scientists used both a milling machine and the dental software of vhf camfacture AG

Ammerbuch/Hauppauge, November 3, 2020: In a recent study conducted by the University Hospital of Tübingen, Charité University Medicine Berlin, and the First State Medical University of Setchenow in Moscow, the milled prosthesis materials exhibit better surface properties than comparable test objects from a 3D printer or from conventional production.

The aim of the study from summer 2020 was to examine subtractive and additive samples for their mechanical polishability. Prosthesis materials obtain a smoother surface after polishing. This is particularly relevant with regard to plaque accumulation. Common prosthetic aids must meet certain qualitative criteria for a successful rehabilitation of edentulous patients, including a surface that is as smooth as possible. Abrasive wear during chewing or mechanical cleaning, poor dental hygiene and reduced salivation can lead to increased plaque accumulation and diseases. For this reason, either mechanical or chemical polishing and also coating processes are applied to reduce the microbial adhesion of the denture surface.

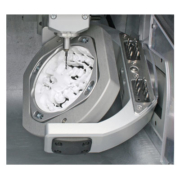

Three groups of materials have been produced and examined for the study: conventionally produced denture bases, which are manufactured by cold polymerization of PMMA, denture samples milled with a vhf S1 and test objects from a 3D printer. Ten samples from each group were left untreated. Another ten objects were pre-polished and ten final samples were polished to a high gloss. Afterwards the surface values of the samples were compared among other criteria.

For the fabrication of the milled prosthesis sample, one specimen was designed virtually in a CAD software and the stereolithography file (STL) was then exported to the vhf software DentalCAM. Afterwards, the file was positioned inside a circular blank made of pre-polymerized PMMA and wet milled with the vhf S1.

The result: in all three categories, the milled samples show clearly better surface characteristics than the 3D-printed and conventionally produced ones. Furthermore, the highly polished samples also show the statistically best surface values.

vhf camfacture AG is pleased about the result and the fact that the vhf S1 milling machine was used for the study. The subtractive method as a whole prevailed and proved superior characteristics. It has been shown that the precise vhf machine could achieve a better surface finish for more advantageous patient care. Thus, the study also proves that it is possible to achieve excellent results with an affordable and easy-to-operate dental milling machine.

The study entitled: Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study, published in the journal Materials, is available online as an open access resource.