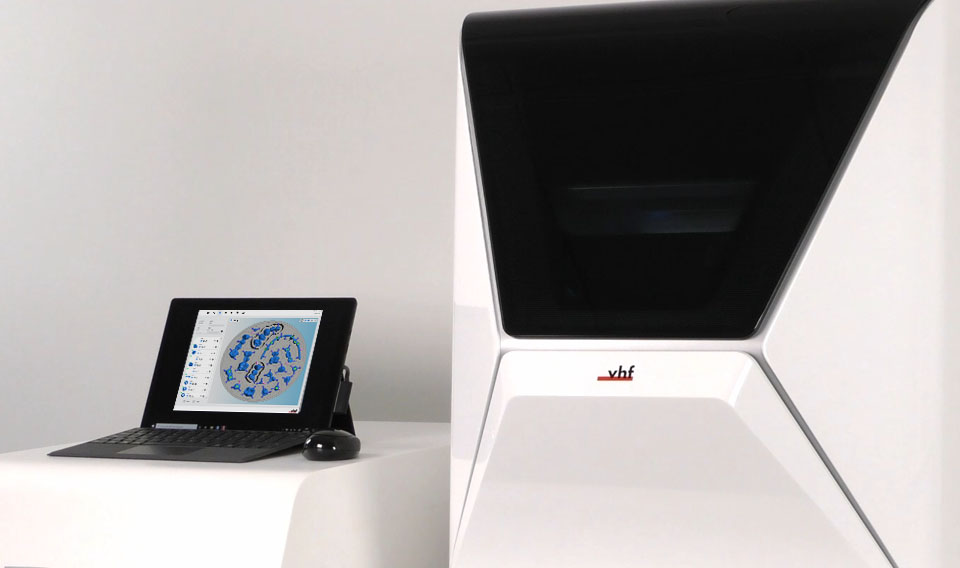

CAM software

vhf dentalcam: the software for the dental future.

CAM software dentalcam including open STL import for all common CAD programs digitizes workflows in the practice and laboratory.

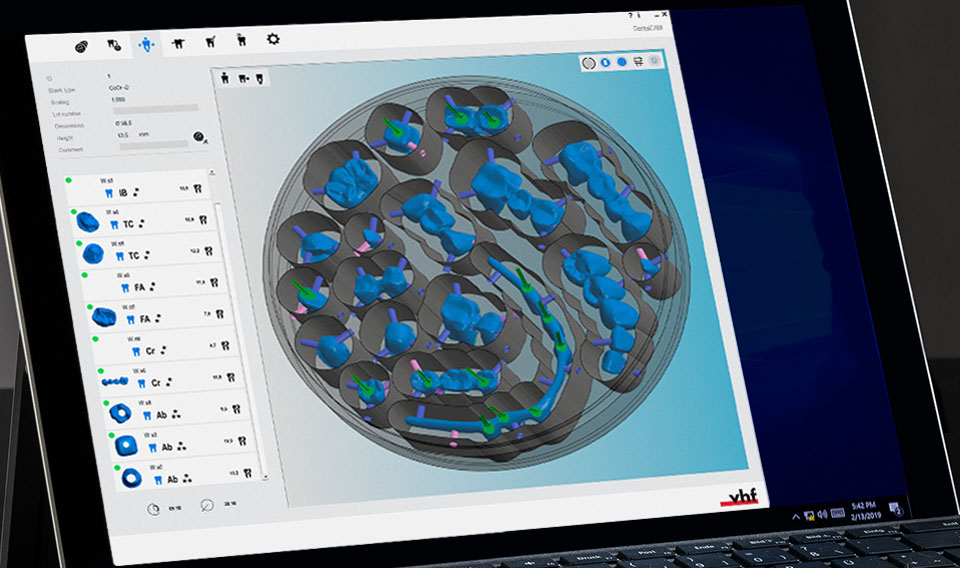

- Perfectly matched to our dental machines

- Intuitive, modern user interface and consistent three-dimensional display of imported work

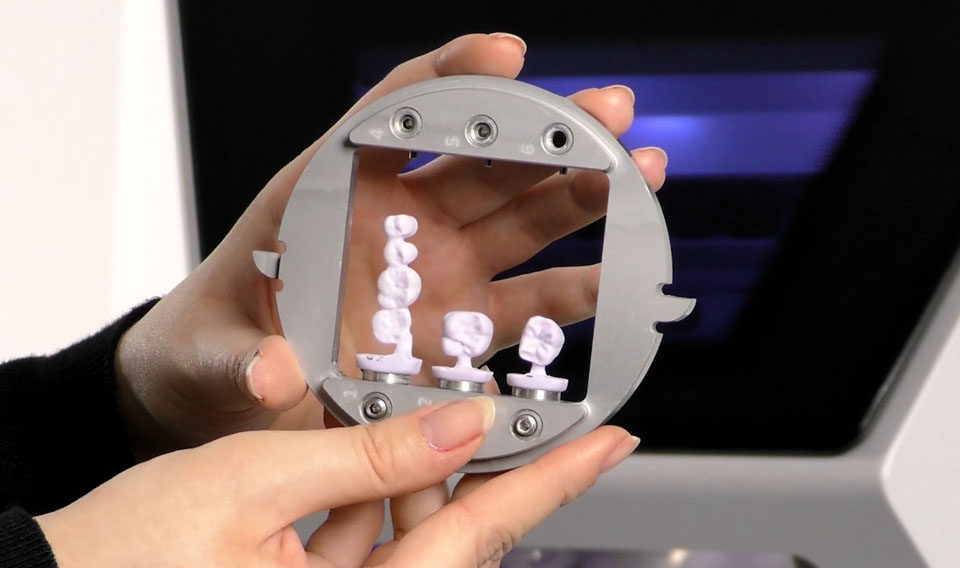

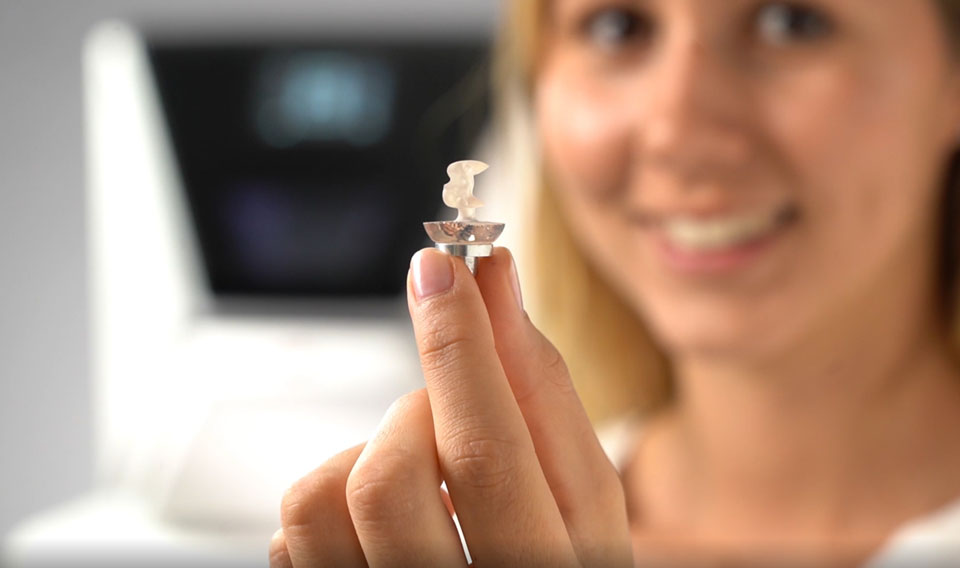

- Production without any prior knowledge

- Thanks to the integrated directmill technology, the workflow from loading a crown to starting the milling machine can be reduced to less than a minute