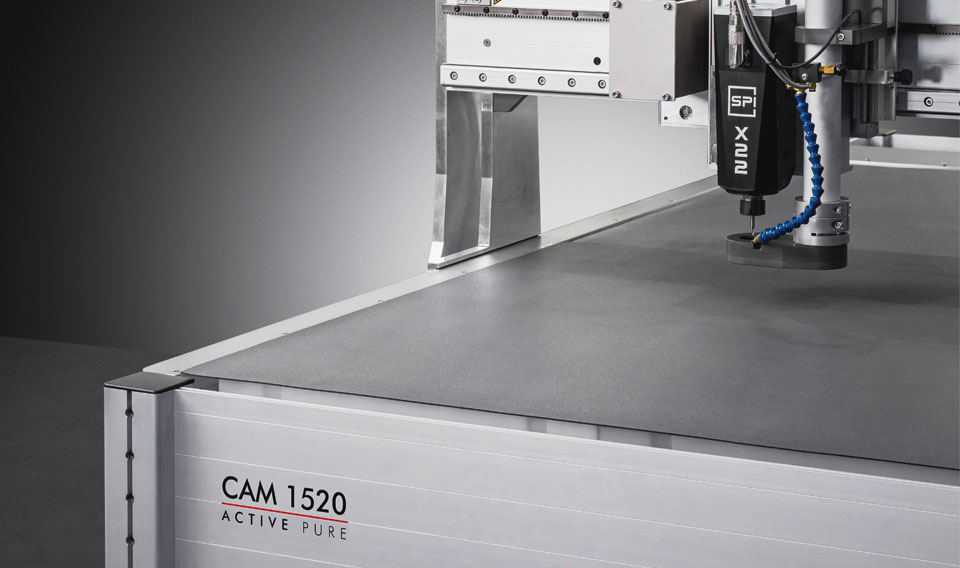

CNC milling machine Active Pure

Your simple and inexpensive entry into professional panel processing.

Your simple and inexpensive entry into professional panel processing.

The Active Pure has optimally matching equipment and is ready for immediate use thanks to the included software. Simply choose between two possible mounting areas: 1.5 × 2 m or 2 × 3 m. The matching tools from our own production are also available directly from vhf – everything from one source.

Getting started in CNC plate processing is easy and affordable with the Active Pure: A predefined equipment package with a focus on essential functional features makes it possible. Without compromising on quality, service and support.

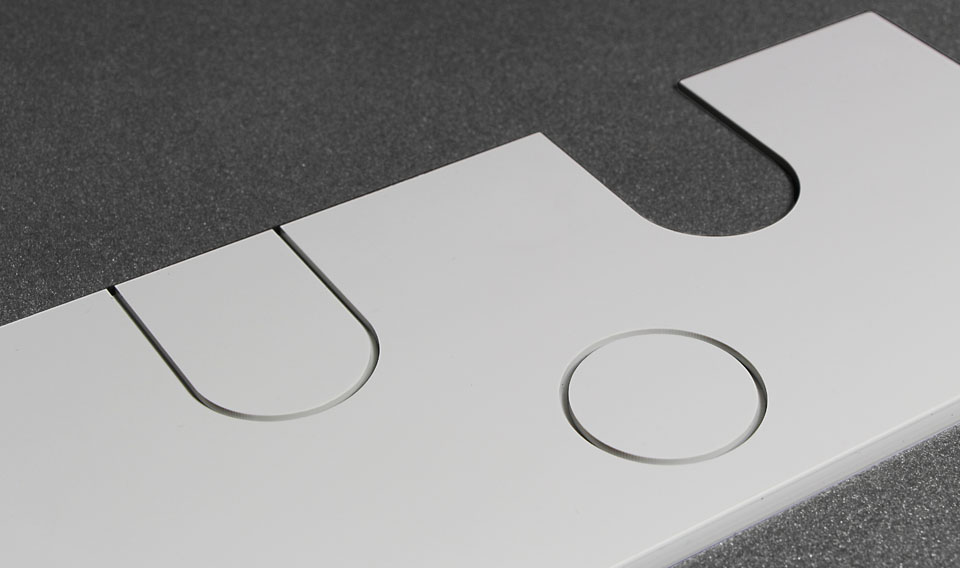

Simply operate the Active Pure for machining metal with any commercially available compressor. Because a complex and expensive compressed air preparation is not necessary for the use of the cooling/spraying unit. Or you can do without compressed air at all. This is possible, for example, for the dry machining of plastics, wood and aluminium composites.

vhf has been building CNC milling machines for 35 years – and this with great success. The special model Active Pure, which is technically based on the proven Active series, also benefits from this success and marks the entry into CNC plate processing. As with all vhf machines, only high-quality industrial components are used for the Active Pure – true to the claim Creating Perfection.

The Active Pure is available in Germany, Austria and Switzerland including free delivery, setup and instruction. For other countries, we will be pleased to provide you with favorable rates on request. vhf experts are always available for advice and can be reached via a free support hotline.

BASIC SYSTEM

Two sizes available: 1,500 × 2,000 mm or 2,000 × 3,000 mm

High-strength aluminium panel profiles

– Reversed rack-and-pinion drive with precise double linear guides and hybrid motors for X and Y axis

– High-revving hybrid motors with gearing for X and Y axis

– Z axis with ball screw spindles free from backlash with flanged bearings

± 0.05 mm X/Y axis, ± 0.01 mm Z axis

180 mm/s X/Y axis

Workpiece changes in a matter of seconds due to suction units integrated in the machine table with individually switchable zones

EQUIPMENT

Air-cooled rotary current spindle with manual clamping, up to 30,000 rpm, S1 = 2,200 W, ER25 interface, clamping range up to 16 mm shank diameter, labyrinth seal

Reliable chip removal when milling plastics, wood and metals; protection against contact during working process due to monitored suction shoe

Manual cooling and spraying unit

Automatic Z-adjustment

* required field