CNC milling machine X

The X optimally combines precision, power and stability.

The X optimally combines precision, power and stability.

The most innovative CNC milling machine from vhf. On a table area of 2 x 3 m, the machine offers innovative technology Made in Germany, and intuitive ease of operation. As an absolute all-rounder it can do a lot more than just milling. With the optional XtraUnit fitted, it is also the perfect machine for cutting and creasing.

The X is a completely new development and the start of a new era. Experience the impressive bandwidth of the machine in the video and convince yourself of the numerous features that make plate processing even more effective.

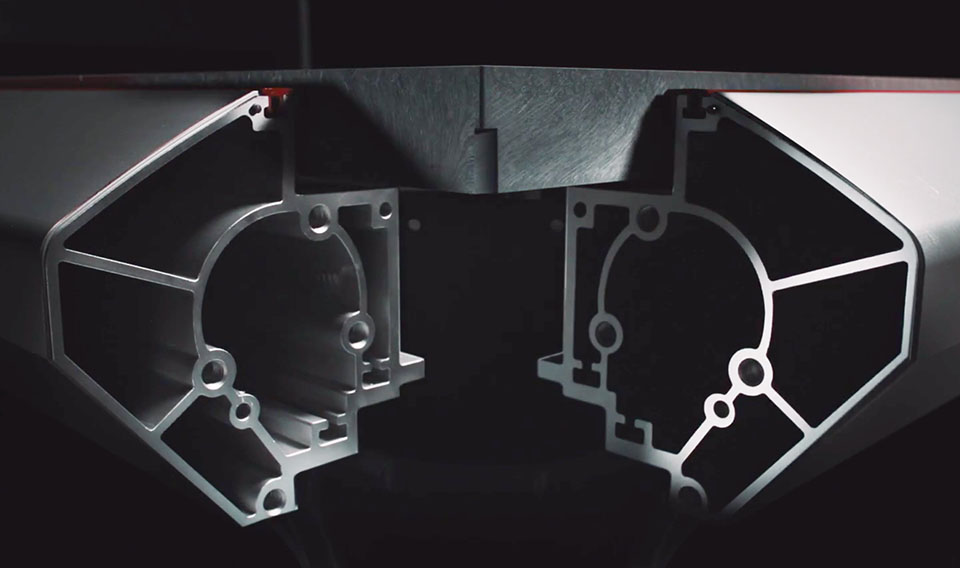

Xstructure: High-tensile aluminum sections deliver extreme rigidity and are filled with the latest technology. Compared with other types of construction, the internal X-shaped honeycomb structure offers maximal resilience at much lower weight. In combination with the machine’s low-vibration cast components this enables the X to run so smoothly. Thought out down to the last detail, in a quality that accepts no compromises – the X.

Xhead: Its powerful 5.8 kW peak output, spinning at up to 40,000 revolutions per minute, makes short work of any material. The X machines panels dependably in many different materials, including aluminum, plastics, wood and stainless steel. On request, an optionally integrable XtraUnit with switchable lance oscillation can process soft materials. V-cut, kiss-cut and creases are also available without difficulty. And all without having to retool!

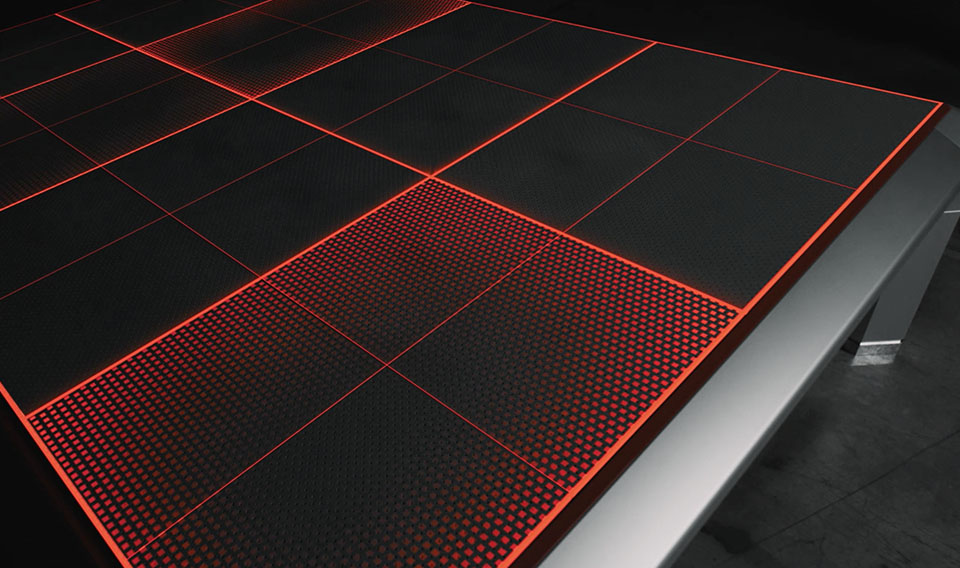

Xvac: Eight vacuum suction units are integrated into the table and monitored by sensors to provide an impressive 1,325 m³ of volume flow for maximum grip. They ensure your panels are securely fastened to the 2 x 3 m table for machining. At the same time the brushless, durable suction units only use as much energy as needed and are surprisingly quiet.

x/y positioning range: 2,045 x 3,050 mm

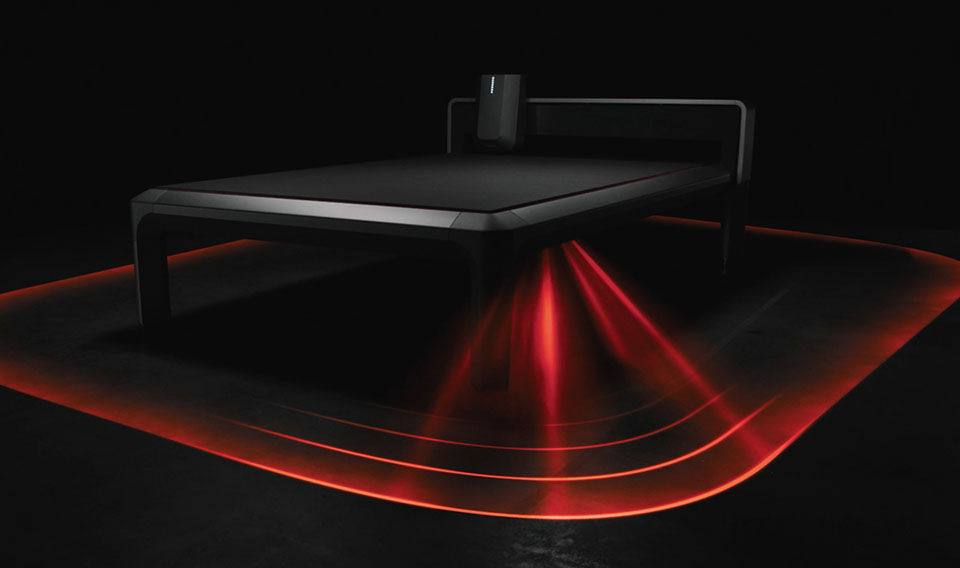

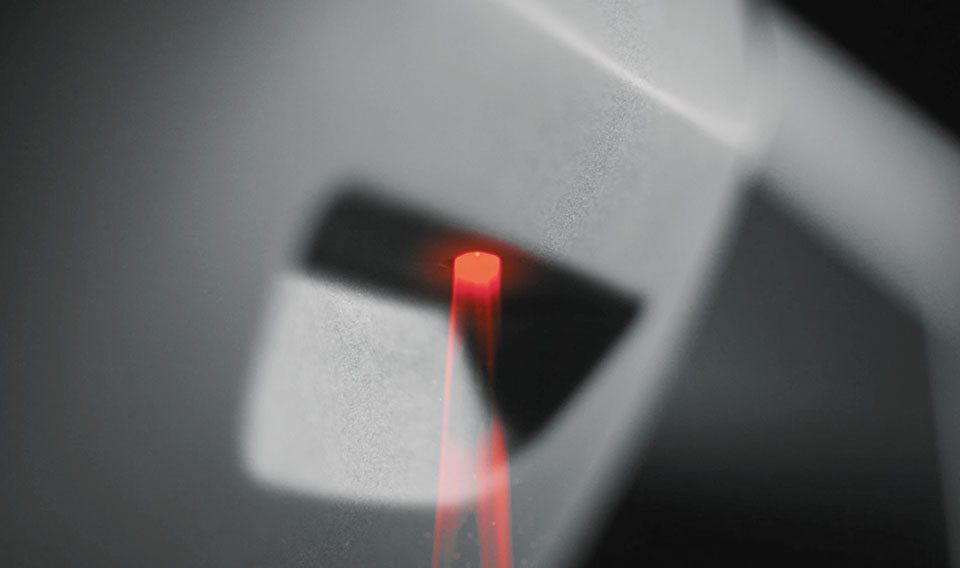

Xscan: The laser safety scanner offers maximum protection without compromising handling. Cutting-edge safety technology, with no distracting light barriers, safety mats or enclosures to disrupt your workflows.

It has never been easier to align your workpieces: the X is equipped with several pneumatic stops that can be set individually to position your workpieces simply and precisely.

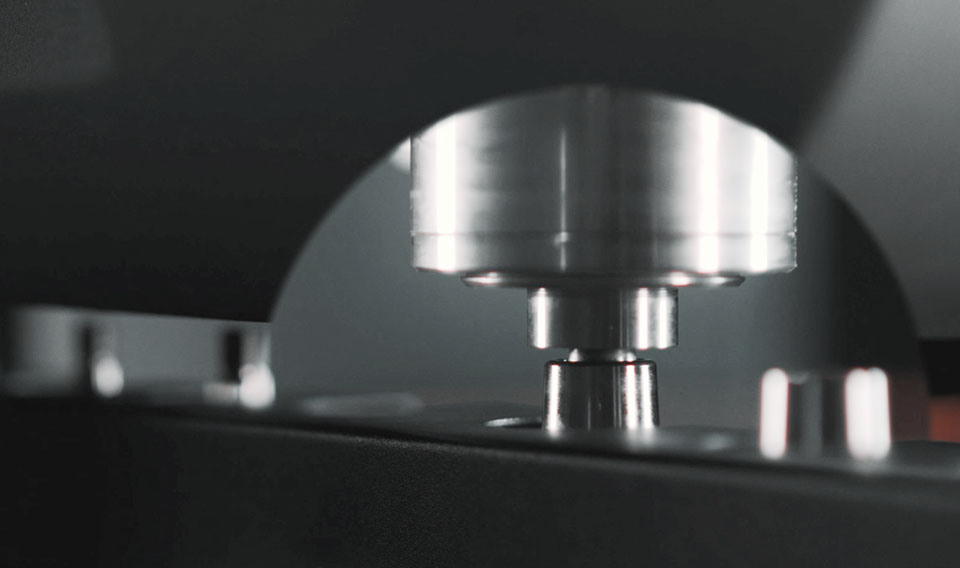

Xtool: Up to 24 tools can be switched in and out as desired. The ability to flexibly and quickly change all HSK-25 milling, cutting and creasing tools is incredibly convenient, time-saving and does not require any manual user intervention.

Xmeasure: The integrated camera makes it possible to move to the workpiece’s zero point conveniently and accurately. Optionally, you can equip your X with automatic register mark recognition for printed workpieces, so that the contour is milled or cut exactly along the print.

TripleXdrive: The innovative drive concept pools the power of three motors per axis, not only increasing the machining speed, but also offering additional accuracy. You will see the result in your workpieces!

Simple operations via a tablet computer, with a clear user interface, let you control your machine quickly and intuitively. Take full advantage of the technical possibilities offered by the X – it’s easy!

With its fully integrated waste removal concept, the X always ensures a clean finish. It adjusts to the ideal height for different workpieces fully automatically.

The minimum quantity lubrication makes it easy to machine metals. And thanks to intelligent integration you can even remove waste and cool at the same time.

The electronic workpiece leveling system gives you perfect engraving and chamfering across the entire machining area, even with material thickness tolerances.

During the AMB trade fair in Stuttgart, vhf presented its latest flagship product: the X. The new CNC milling machine for plate processing optimally combines precision, drive power and stability.

BASIC SYSTEM

2,416 x 3,980 x 1,500 mm

High-tensile aluminium profiles in combination with low-vibration machine cast elements

Rack-and-pinion drive with 3 motors per X/Y axis, ball screw spindles in Z axis

± 0,02 mm X/Y axis, ± 0,01 mm Z axis

Max. 566 mm/s X/Y axis, max. 110 mm/s Z axis

Approx. 1,200 kg

VACUUM TABLE

Table size of 2,050 x 3,050 mm; 8 controlled suction units; maximum volume flow of 1,325 m3/h

SPINDLE

Water cooled rotary current spindle, up to 40,000 rpm, S1 = 2,500 W, Pmax = 5.8 kW, HSK-25 connection, clamping range up to 10 mm shank diameter, sealing air

S1: mechanical output power under continuous load of the spindle (100 % machining time)

Pmax: maximum mechanical output power of the spindle

SERIENAUSSTATTUNG

Automatic 12-fold tool changer for all milling, cutting and creasing tools; including measuring, expandable to 24 stations

Electronically controlled minimum quantity lubrication system

Integrated dust extraction unit with automatic adjustment to material height

Five individually pneumatically activated workpiece stoppers

Fully automated due to integrated precision measuring key

Visual via integrated camera system

Matrix measurement by integrated measuring key, compensation by control electronics

Barrier-free safety area due to laser scanner and separately operated safety cover on the machining unit with fully automatic adjustment to the material height

Wireless touch-pad control, including all respective machine components

ADDITIONAL EQUIPMENT

Oscillated cutting, creasing, V-cut, straight-cut and kiss-cut; tools are automatically changed and measured

Extension to 24-fold tool changer

Recognition of register marks and automatic correction of milling and cutting paths

* required field