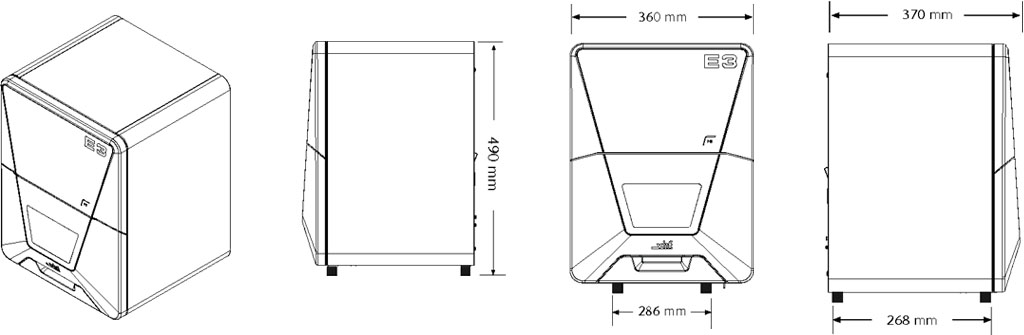

E3. For the processing of occlusal appliances.

Automate your workflow.

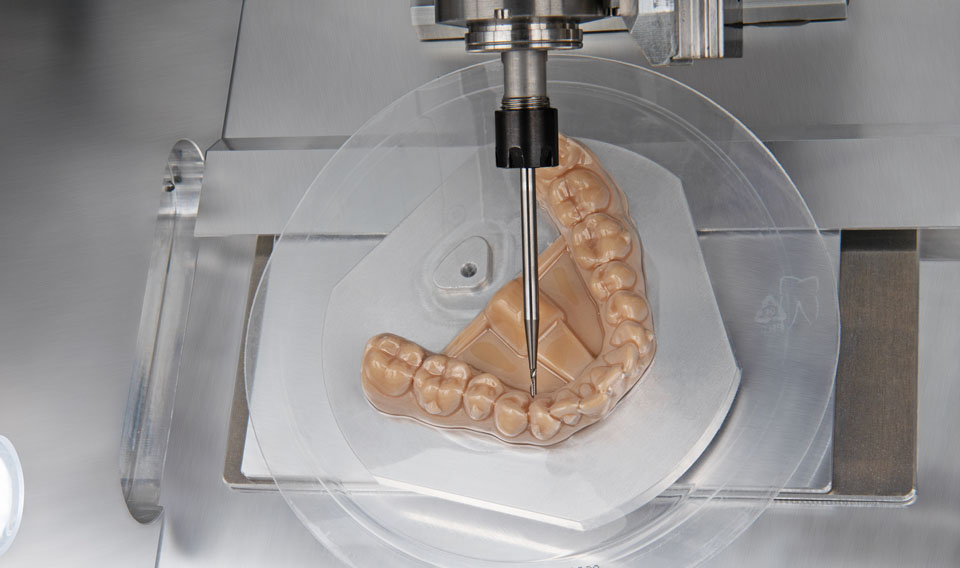

The new E3 enables you to automate the precision trimming of occlusal appliances. You can expect the very best results in the shortest time. The machined fabrication also ensures a consistently high quality.

The E3 is simple to commission and operate, and fits seamlessly into your workflows. Our in-house developed TRIMCAM software automatically recognizes the trimline on which the occlusal appliance is milled out from the available planning data. So, you’ll get started right away.

True to the motto: unpack, connect, start milling!

Axes

Aligner

Seconds

Tool

Do you have a question?

Or would you like to receive more information?

Contact form

* required field

EASE CLASS

Our EASE CLASS machines have in common their freedom from compressed air, their compact design with low weight, and their service-friendly concept: Premium dental restorations made easy.

Occlusal appliances

Occlusal appliances