E4. For easy entry into same-day dentistry.

The innovative milling machine.

Impress your patients with a quick and comfortable treatment and produce perfect restorations – easily and in just one session. Your patients won’t thank you enough.

With a machine weight of only 28 kg and no use of compressed air, the E4 offers maximum flexibility in terms of installation. You can set the E4 anywhere. True to the motto: unpack, connect, start milling!

Axes

Discs

Block

Tools

Axes

Discs

Block

Tools

“I’d never have thought that same-day dentistry could be so easy. A seamless workflow from the intraoral scanner to

the perfect restoration, which I can use with virtually no reworking. My patients are impressed with the quick treatment in one session.”

Highlights

Chairside production is so easy

The new E4 makes it so easy for you to get started with chairside production of dental restorations, and gives you maximum freedom. Combine the E4 with your preferred intraoral scanner, any CAD software and materials that are appropriate for your individual patients. The E4 is the heart of your workflow and produces the perfect restoration for you.

The integrated CAM software enables you to get started right away!

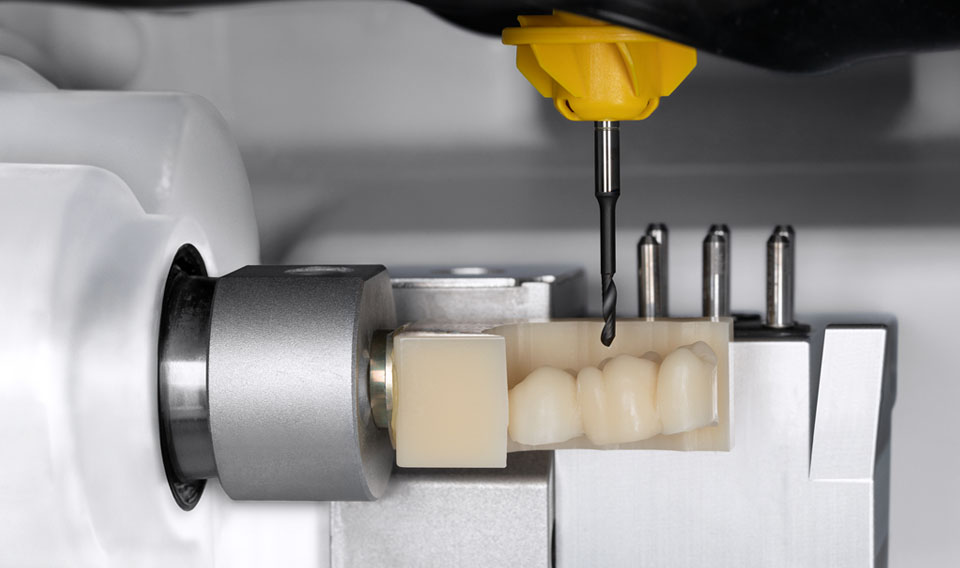

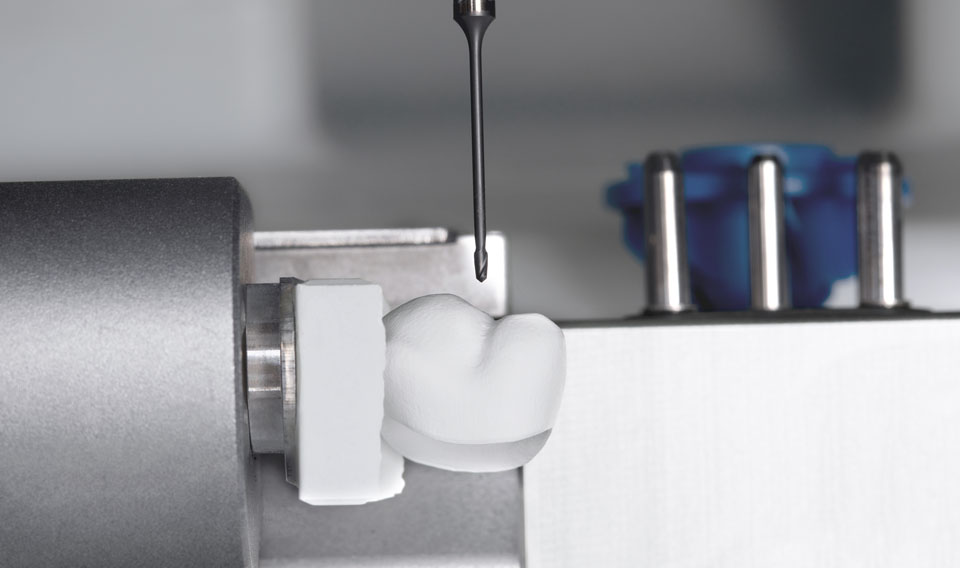

The all-rounder for blocks

The E4 has many talents. Wet grind glass ceramics or composites with ceramic content and dry mill materials such as zirconia and PMMA.

A small change with a big effect. Benefit from easy switching: Insert the tank for wet processing or the optional container for machining dust and start processing high-quality restorations. A special filter mat in the liquid tank ensures that the tank is free of chippings.

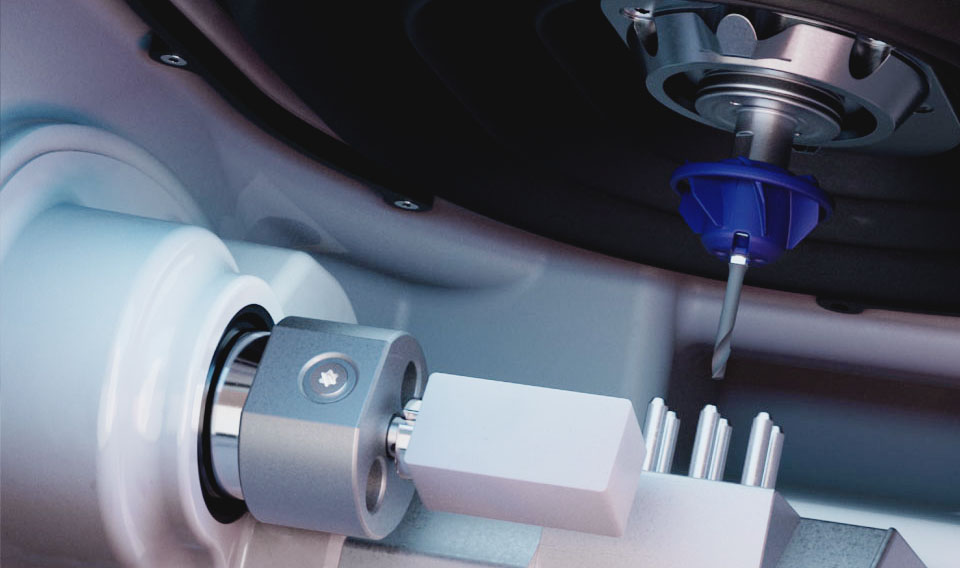

No compressed air with the innovative technology

One great innovation of the E4 is that it does not use compressed air: The E4 requires neither an external compressed air connection nor an integrated compressor, which is only possible with our patent-pending AIRTOOL.

The AIRTOOL turbine blades use the speed of the high-frequency spindle to generate a powerful air flow, which keeps the workpiece free from dust and chippings. They are removed by vacuum from a dust collector.

Wet grinding

The PUREWATER Technology ensures that the closed liquid circuit in the machine requires no grinding additives. For you, this means easy disposal and even lower running costs.

Dry milling

The optional dry container enables you to mill materials such as zirconia, PMMA and various composites with your E4 with no cooling water or compressed air.

Experience the E4 interactively

Experience the E4 interactively and make an appointment for a consultation.

“I’m totally won over by the vhf dental milling machines”

The decision to invest in the E4 and E5 dental milling machines wasn’t difficult for Dr. Tim Wiesner. Since purchasing the two devices in the new vhf EASE CLASS product series, they’ve been operating almost every day. In our conversation at his Tübingen dental practice, he explains why he chose the two vhf machines and explains his route to digital chairside production.

Features

Innovative

- No compressed air required with the patent-pending AIRTOOL

- Machine design optimized for minimal weight

- Multi-compartment for cooling liquid tank or optional dry milling container

- Modular machine design to optimize servicing and maintenance

Fast & precise

- 800 W 60,000 rpm spindle

- 3 μm repetition accuracy

- Sturdy aluminum welded construction

Independent

- DENTALCAM software with open interface to CAD software and materials

- Virtually any intraoral scanners can be used

- Grinds and mills almost all block materials up to 45 mm long from numerous manufacturers

- A full range of materials for glass ceramics, composites, zirconia and plastics

Reliable

- 100% developed and manufactured in Germany

- Optimum manufacturing results and high durability with only premium quality industrial components

- 24-month guarantee

Cost-effective

- Sustainable operation with no compressed air

- The PUREWATER Technology ensures that no grinding additives are required for the cooling liquid

- Environmentally friendly shipping due to low weight of machine

- The excellent price-performance ratio ensures a cost-effective entry into in house production

- Extremely simple operation with provided DENTALCAM software featuring DIRECTMILL Technology – no license fees

Material, manufacturer, indication

Enjoy great freedom of choice.

| Composites | PMMA & Wax | Glass ceramics | Zirconia |

Crown | Bridge |  Inlay | Onlay |  Veneer |  Abutment |

Screw-retained crown |

Be sure to review local and/or national regulations and/or regulations by other authorized organizations or entities (e.g. professional associations, health authorities).

Download

Technical Data

GENERAL

Fields of application

Wet/dry machining

Materials

Composites, plastics/wax, glass ceramics, zirconia

– Blocks up to 45 × 20 × 20 mm

Indications

Crowns, bridges, inlays, onlays, veneers, zirconia abutments, Screw-retained crowns

Holder systems

Integrated block holder

BASE SYSTEM

Construction

Sturdy aluminum welded structure

Housing

White high-gloss lacquer finish · upward opening lift door to the workroom

Number of axes

4

Linear axes X-/Y-/Z-axis

Precision ball screws · motors with resolution < 1 μm · ground precision guides made of high-alloyed steel · repetition accuracy ± 0.003 mm

Rotary axis A-axis

Rotation angle: +190° to –10°

Control unit

5-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware- based real-time operating system with standardized instruction set · FPGA-integrated processor · updateable hardware · real-time path and ramp calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface

Lighting

Backlit workspace through RGB LED lighting with status indication

SPINDLE

General

High-frequency spindle with electromechanical tool change

Speed

Up to 60,000 rpm

Power

Peak power (Pmax): 800 watts · nominal power (S6): 400 watts · continuous power (S1): 300 watts

Bearing

2-fold hybrid ceramic ball bearing

Collet

For tools with 3 mm shank diameter and max. 40 mm total length

AUTOMATION

Tool change

Removable tool magazine for 6 tools with additional space for one AIRTOOL · length measurement and tool breakage monitoring via precision measuring key · access via working chamber flap, safety-locked

Access combination compartment

Direct insertion of the coolant tank or (optional) dry container in compartment directly under the working chamber

PROCESSING MODES

Wet

2 fluid nozzles on the spindle · integrated cooling liquid tank · PUREWATER Technology: no grinding additives required

Dry

Compressed air-free operation through use of AIRTOOLs · hose connection for external suction unit on the back of the housing · 24 V switch output for controlling suction units · optional dry container required

CONNECTION REQUIREMENTS

Compressed air

–

Power supply

100–240 volts · 50/60 Hz, 500 watts

Extraction system

Extraction filter class M, 2,500 l/min extraction capacity at 220 hPa

Data

10/100/1000 MBit/s BaseT port (auto-sensing) Ethernet via RJ-45 socket

ENVIROMENTAL CONDITIONS

Operating temperature

Between 10 °C and 35 °C

Air moisture

Max. 80 % (relative), non-condensing

APPROVALS

All models

CE

North America model

UL 61010-1, CAN/CSA C22.2 No. 61010-1

DIMENSIONS & WEIGHTS

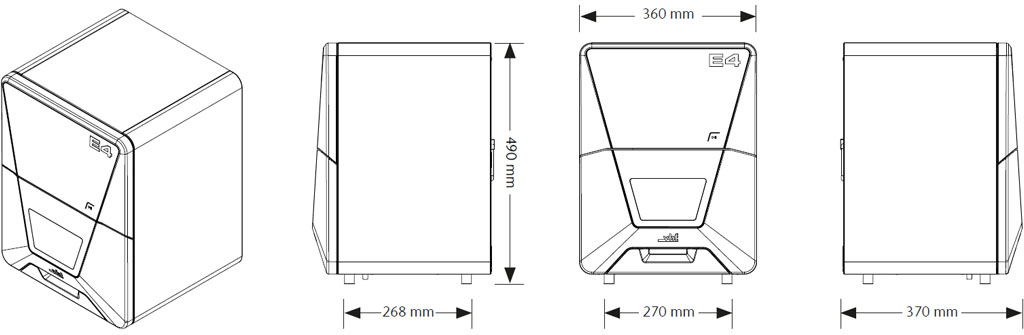

Dimensions (W/D/H)

360 × 370 × 490 mm with closed door · 360 × 420 × 490 mm with open door

Footprint (W/D)

270 × 268 mm

Weight

28 kg

SCOPE OF DELIVERY

CAM Software

DENTALCAM software included

Accessories

Spindle service set · calibration set incl. stirrup measuring screw · tool magazine inserts (1 piece) · Torx wrench set · torque driver 1.5 Nm · AIRTOOL for wax and plastics · drill bit (tool positions) · cleaning brush and microfiber cloth · TecPowder (3) · foam filter · power cable · Ethernet network cable

Contact form

* required field

EASE CLASS

Our EASE CLASS machines have in common their freedom from compressed air, their compact design with low weight, and their service-friendly concept: Premium dental restorations made easy.