Milling and 3D printing in dental technology

What is the difference and which technology should I choose?

For 35 years, we at vhf have been passionate about milling technology and have continued to develop and improve it. Dental restorations in particular are subject to the highest quality requirements. But can these only be achieved by milling or grinding? After all, 3D printing is currently on everyone’s lips, including in the dental industry.

When selecting the appropriate manufacturing technology – subtractive such as milling or additive such as printing – the decisive question is for which purpose the work is being done. Printing technology offers certain advantages in the manufacture of models and drilling templates, for example in terms of speed and cost-effectiveness. However, milling technology can play to its strengths when it comes to permanent restorations where durability, health protection, aesthetics, material diversity, and precision are decisive.

Not only perfect aesthetics are crucial for dental restorations; high durability and excellent biocompatibility are also decisive factors for a lasting, radiant smile.

Durability: High-quality ceramics for permanent restorations

Millable ceramic materials such as lithium disilicate (e.g., the popular IPS e.max from Ivoclar) and zirconium oxide do not contain any organic binders – their ceramic content is therefore almost 100 percent, making the material stable and homogeneous from the outset. This results in excellent long-term durability and minimizes the risk of material fatigue in the mouth.

Some 3D printing materials have also been developed for permanent restorations and have a comparatively high proportion of ceramic particles, accounting for over 50 percent of their weight. However, a significant portion of the material still consists of synthetic resin, which serves to bond the layers during the printing process. Synthetic resin has a significantly lower flexural strength than ceramic, which is also reflected in the figures: while a printed crown made of hybrid resin achieves around 80 to 150 megapascals, milled lithium disilicate achieves around 500 megapascals. Zirconium oxide even achieves 900 to 1,200 megapascals. In addition, synthetic resins can degrade over time, which compromises the stability and durability of the restoration.¹

Environmental and health protection: non-toxic and biocompatible

Ceramic and metal blanks are practically inert, i.e., biocompatible and safe – both during processing and in the patient’s mouth. This has been proven through decades of use and certified accordingly. Since these materials do not cause toxic reactions, there is no risk of subsequent inflammation or allergic reactions. The post-processing steps in milling are limited to polishing or sintering, without any further chemical reaction processes.

The synthetic resin materials used in 3D printing often contain toxic chemicals such as acrylates and isocyanates. During the printing process, vapors and dust are produced that can pose a health risk to those involved in the manufacture of the restoration.²

Printed restorations also remain toxic if they are not properly cured. However, even cured materials can be cytotoxic³ and could cause inflammation, tissue damage, and allergic reactions in the mouth.

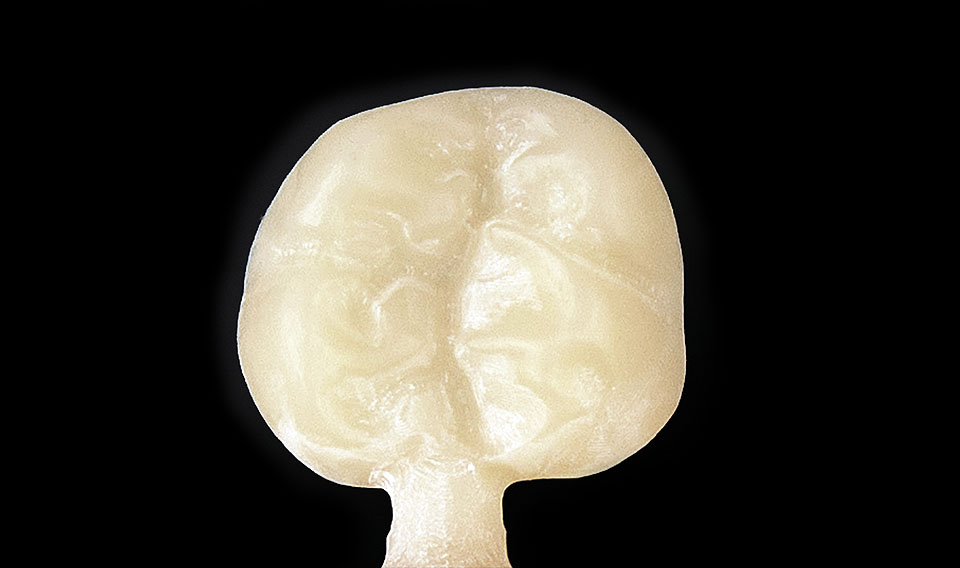

Aesthetics: unmatched natural appearance

Lithium disilicates and modern zirconia materials already offer high aesthetic quality and often require minimal or no additional characterization to achieve a natural appearance.

Glass ceramics distinguish themselves by exceptional translucency. Their light-optical behavior is similar to that of natural tooth structure – they appear lifelike and have a deep effect. Zirconia is available in multi-layered materials that combine different color gradations and transparencies. For highly aesthetic temporary restorations, multilayer PMMAs can be used, which already have color gradients integrated. They offer an attractive result with greater naturalness than single-color plastics.

Printing multilayer synthetic resin materials, on the other hand, is only possible with complex and expensive technology, which nevertheless cannot achieve the same high aesthetic quality as millable materials.⁴ Printing can be a cost-effective option for the manufacture of temporary restorations and drilling templates. These materials are also not subject to the requirements for long-term durability in the oral cavity because they are only used for a short time and without mechanical stress.

Wide range of applications and materials for milling: The directclean Technology of the R5 allows you to switch between wet and dry processing as desired without any changeover work. Here: wet grinding of glass ceramics and dry milling of zirconium.

Wide variety of materials and flexibility

A single milling machine can process a wide range of materials, from wax and plastics to ceramics and metals. This versatility ensures flexibility in everyday laboratory work, reduces investment costs, and simplifies training because the operating concept remains the same for each machine.

3D printers, on the other hand, are usually designed to print only one class of material, as the technologies for printing different materials are fundamentally different. Digital light projection (DLP), stereolithography (LCA), or selective laser melting (SLM) are used here. For the same range of indications, 3D printing therefore requires a larger machine park, or work must be outsourced.

Precise and predictable results with high surface quality

The repeat accuracy in milling is in the single-digit micrometer range. Depending on the tools used and the milling strategy, the precision of the tooth restorations is excellent, and the fit is very consistently reproducible when the correct procedure is followed. After all, in dentistry, tiny deviations determine whether a restoration fits perfectly or requires time-consuming re-grinding. Milled surfaces also have a very high quality, which reduces plaque accumulation on prosthesis surfaces, for example.⁵

3D printing also has a high resolution, but the predictability in terms of fit is not comparable to milled restorations.⁶ In addition, the support structures that are unavoidable for printing and must later be removed and smoothed manually are often located in critical areas – for example, on the chewing surface of a crown. On the other hand, 3D printing also enables complex geometries that are difficult to achieve with traditional milling techniques.

When milling a crown, a retaining bar remains in place, which has been attached to the side of the tooth in a relatively inconspicuous manner. It can be easily removed by hand. The support structure of 3D printing consists of several thinner bars, which are often located directly on the chewing surface. Removing them is much more difficult, and the fine details of an elaborately constructed chewing surface are lost in the process. Residues of the printing resin are still visible here as a white layer.

Over 40 years of proven milling results in dentistry

Dental ceramics have been milled and ground for decades. Whether glass ceramics or zirconia, there is proven long-term clinical success and scientific long-term studies that demonstrate their durability.⁷ This experience provides reassurance for dentists and patients. For example, in many studies, the survival rate of ceramic crowns after ten years is more than 90 percent.

This is not the case with printed materials, as they are generally relatively new to the market and there is a lack of reliable long-term data. Some time ago, a well-known manufacturer even had to restrict a new hybrid material to certain indications after crowns had detached on a large scale in practice.⁸

Faster production with less preparation and follow-up work

When comparing production times, the entire production process must be taken into account. The milling machine is immediately ready for use and milling materials require no preparation. After milling, the retaining bars are removed and smoothed, and the restorations are then cleaned with compressed air. Most materials must finally be sintered or crystallized in a furnace; however, the time required for this has been significantly reduced thanks to technological advances.⁹

With 3D printing, pre- and post-processing take more time. Printable materials often have to be mixed and heated for a long time before they can be used. However, this effect becomes less significant with larger quantities.

Even after printing, several steps still have to be carried out, such as cutting and smoothing the more complex support structure, various cleaning processes, curing resin-based materials with a UV light device, or sintering ceramic materials in a furnace. Finally, the surface is smoothed with a rotating instrument. These processes are necessary to achieve a safe and clinically usable result, but they cost time and personnel.

Grinding glass ceramics with maximum precision: thanks to repeat accuracy in the micrometer range, there is no need to compromise on fit accuracy. This means that thin preparation margins can be produced even with sensitive materials such as glass ceramics in an uncrystallized state.

So which technology is suitable for which indication?

Additive manufacturing process

It appears that additive and subtractive manufacturing processes can be considered complementary technologies: 3D printing is suitable for surgical templates, models, and temporary restorations, which can be produced in this way quite flexibly and cost-effectively. In other words, for anything that does not require the highest quality and does not remain in the patient’s mouth for a long time.

Hybrid processes

However, hybrid processes are also emerging, in which a workpiece is first additively built up from cobalt-chromium or titanium using laser melting and then subtractively reworked at fit-relevant points on a high-precision milling machine. The remaining rougher surfaces of the laser-sintered metal are then ideal for veneering with plastic. Here, both the greater design freedom of laser melting and the precision of milling can play to their strengths; however, the process is limited to quite specific indications.

Subtractive manufacturing process

Milling is clearly the first choice for permanent restorations due to its superior durability, biocompatibility, precision, and aesthetic quality. The argument that 3D-printed restorations are supposedly cheaper is only partially true: while block materials are still expensive, the prices for discs made of zirconium oxide, for example, have fallen significantly in recent years. In addition, high-quality materials for printing permanent restorations are also more expensive than the materials often used for temporary restorations for price comparison purposes.