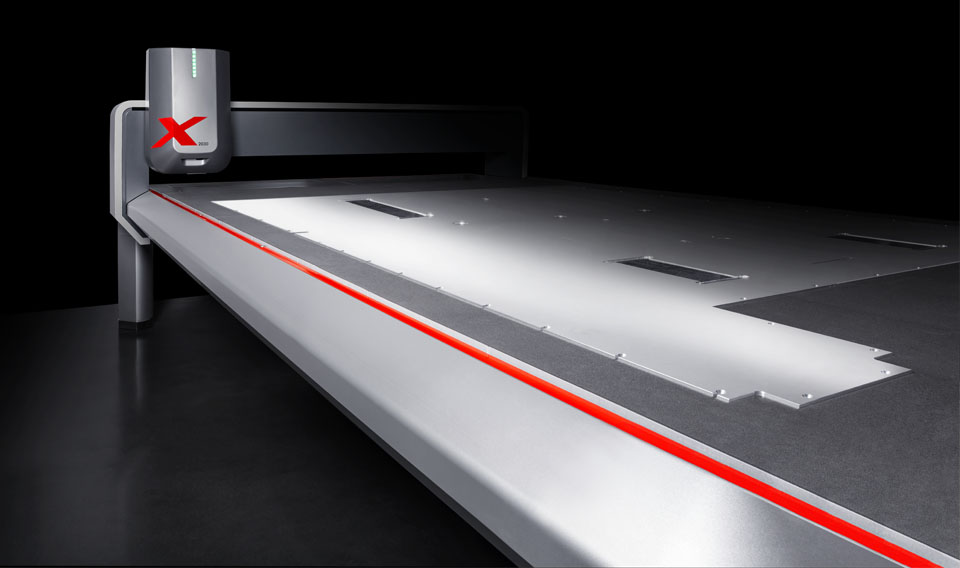

Reduced effort for machine operation and faster processing

Processing larger panels offers several advantages: The operating time per workpiece is reduced to a minimum because you can mill several workpieces from one panel very efficiently and processing is no longer interrupted by frequent material changes. In addition, with this non-stop processing, tool changes are only carried out once per panel and not per workpiece, which saves you even more valuable time.

Easy handling and full flexibility with efficient material utilization

Fixing the panel by vacuum or setting the zero point is also extremely easy, as working from the large panel does not require the same alignment accuracy as milling workpieces to size.

In addition, any workpiece size can be produced from large panels – from small to large formats, everything is possible. The use of holding bars means that even very small workpieces can be reliably fixed to the vacuum table. This allows you to react flexibly to changing orders.

Basically, the larger the panel, the better the material can be utilized through an optimized arrangement of the workpieces, which enables particularly economical work. The material is used efficiently and waste is minimized, which in turn reduces your material costs and contributes to environmentally friendly production.